Mechanical Principle Of Plunger Pump

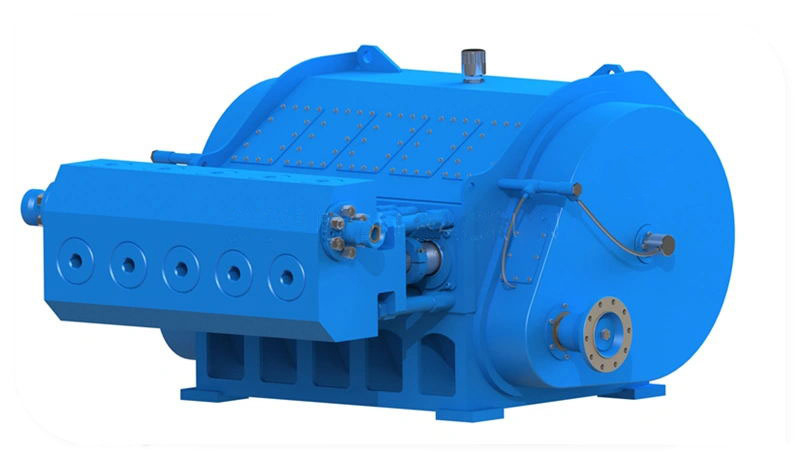

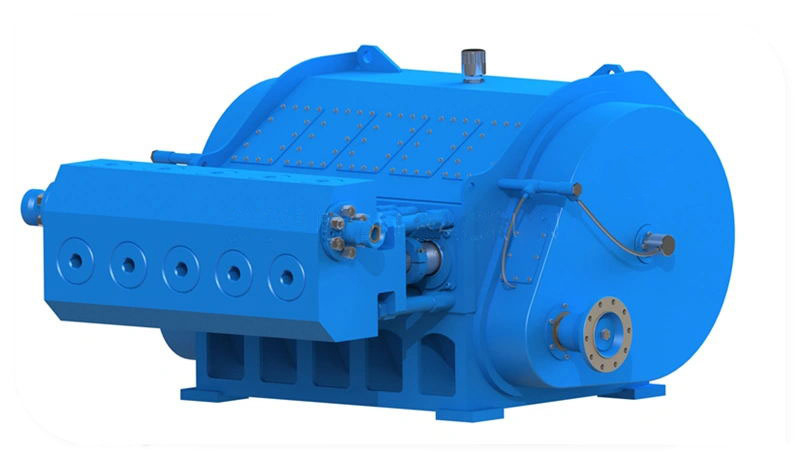

High quality plunger pump is an important device in hydraulic system. It depends on the plunger reciprocating movement in the cylinder, so that the volume of the sealing chamber changes to achieve oil absorption and oil pressure. The practical plunger pump has the advantages of high rated pressure, compact structure, high efficiency and easy flow regulation. Plunger pump is widely used in high pressure, large flow and flow need to adjust the occasion, such as hydraulic press, construction machinery and ships.  Content introduction High quality plunger pump plunger reciprocating total stroke L is constant, determined by the CAM lift. The amount of fuel the plunger can supply per cycle depends on the fuel supply stroke, which is not controlled by the camshaft and is variable. The beginning of the oil supply does not change with the change of the oil supply stroke. Rotation of the plunger can change the oil supply time, thus changing the oil supply. When the practical plunger pump works, under the action of the CAM on the camshaft of the injection pump and the plunger spring, the plunger is forced to make up and down reciprocating motion, so as to complete the pumping task. The pumping process can be divided into the following two stages. Feeding process When the convex part of the CAM is turned over, under the action of the spring force, the plunger moves down, the upper space of the plunger (called the pump oil chamber) produces vacuum, when the plunger end face opens the oil inlet hole on the plunger sleeve, the diesel oil filled in the upper body of the oil pump enters the pump oil chamber through the oil hole, the plunger moves to the bottom dead center, and the oil inlet ends

Content introduction High quality plunger pump plunger reciprocating total stroke L is constant, determined by the CAM lift. The amount of fuel the plunger can supply per cycle depends on the fuel supply stroke, which is not controlled by the camshaft and is variable. The beginning of the oil supply does not change with the change of the oil supply stroke. Rotation of the plunger can change the oil supply time, thus changing the oil supply. When the practical plunger pump works, under the action of the CAM on the camshaft of the injection pump and the plunger spring, the plunger is forced to make up and down reciprocating motion, so as to complete the pumping task. The pumping process can be divided into the following two stages. Feeding process When the convex part of the CAM is turned over, under the action of the spring force, the plunger moves down, the upper space of the plunger (called the pump oil chamber) produces vacuum, when the plunger end face opens the oil inlet hole on the plunger sleeve, the diesel oil filled in the upper body of the oil pump enters the pump oil chamber through the oil hole, the plunger moves to the bottom dead center, and the oil inlet ends  Oil return process The plunger supplies oil upward, and when it goes up to the chute on the plunger (stop supply side) and the oil return hole on the sleeve, the low pressure oil circuit of the pump oil chamber communicates with the middle hole and radial hole and chute of the plunger head, the oil pressure plummets, and the oil outlet valve quickly closes under the action of the spring force to stop the oil supply. After that, the plunger goes up, and when the CAM bulge is turned over, the plunger goes down again under the action of the spring. At this point the next cycle begins. High quality plunger pump with a plunger for the principle of introduction, a complex plunger pump has two one-way valves, and the opposite direction, when the plunger moves in one direction there is negative pressure in the cylinder, then a one-way valve to open the liquid is sucked into the cylinder, the plunger moves in the other direction, the liquid will be compressed after another one-way valve is opened, the liquid is sucked into the cylinder is discharged. This mode of operation after continuous motion to form a continuous oil supply.

Oil return process The plunger supplies oil upward, and when it goes up to the chute on the plunger (stop supply side) and the oil return hole on the sleeve, the low pressure oil circuit of the pump oil chamber communicates with the middle hole and radial hole and chute of the plunger head, the oil pressure plummets, and the oil outlet valve quickly closes under the action of the spring force to stop the oil supply. After that, the plunger goes up, and when the CAM bulge is turned over, the plunger goes down again under the action of the spring. At this point the next cycle begins. High quality plunger pump with a plunger for the principle of introduction, a complex plunger pump has two one-way valves, and the opposite direction, when the plunger moves in one direction there is negative pressure in the cylinder, then a one-way valve to open the liquid is sucked into the cylinder, the plunger moves in the other direction, the liquid will be compressed after another one-way valve is opened, the liquid is sucked into the cylinder is discharged. This mode of operation after continuous motion to form a continuous oil supply.

![]() February 09, 2023

February 09, 2023